Comprehensive manufacturing solutions from design to delivery

Every component passes through a complete in-house manufacturing process. From 3D design and model construction to aluminum casting, machining, and final inspection, all steps are handled under one roof. The result is ready-to-use components that are durable, precise, and manufactured in Berlin.

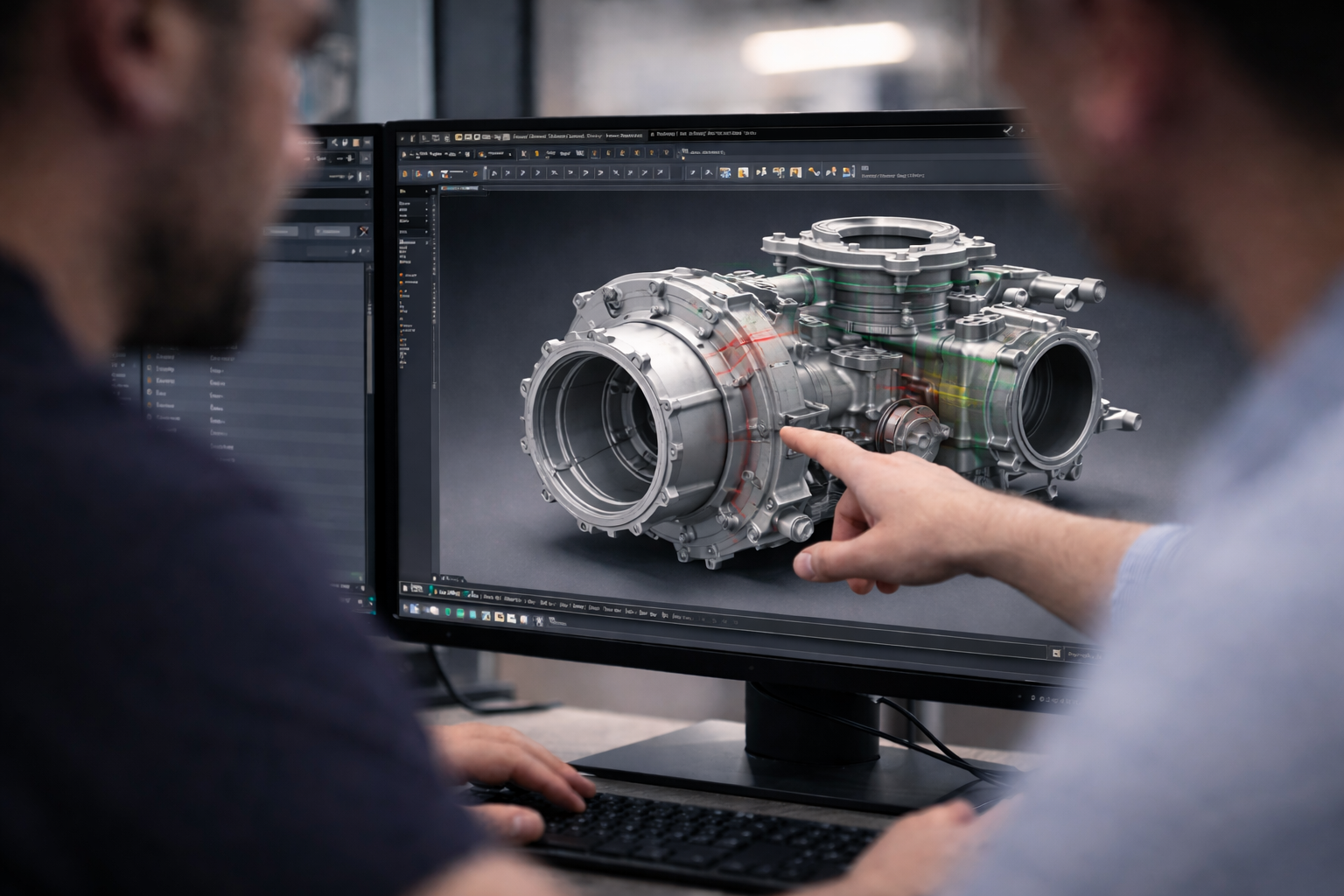

Our specialists optimize your 3D CAD data for the entire manufacturing process, from prototype development to series production. Using advanced CAD and CAM systems as well as simulation tools, we identify and eliminate potential issues at an early stage. This ensures high efficiency, reliable processes, and consistent precision.

We manufacture precise models and molds for our aluminum foundry using advanced 3D milling and rapid prototyping technologies. This allows the realization of complex geometries and short production cycles, always tailored to your specific requirements.

Our in-house aluminum foundry combines short internal workflows, high flexibility, and decades of experience. We offer sand casting and permanent mold casting for prototypes, small series, and serial production. Sustainable electric melting systems and 3D-printed cores enable efficient production and complex component contours.

Our CNC machining centers provide precise turning and milling for single components and serial production. Equipped with 5-axis technology, automation systems, and continuous process optimization, we ensure high flexibility, short lead times, and consistent machining quality.

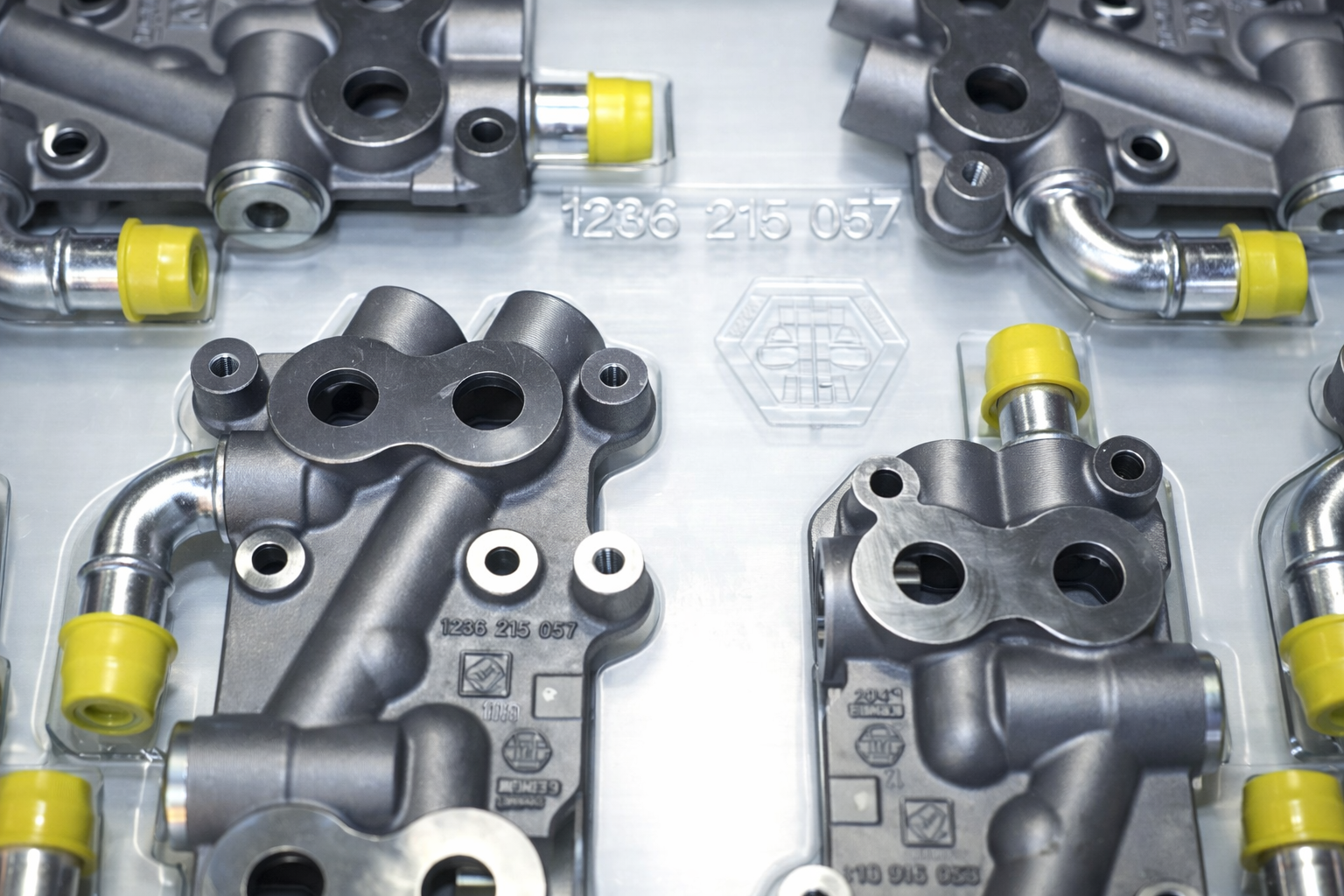

From small batches to high-volume production, our series manufacturing adapts to your requirements. Complete in-house process control ensures reliable delivery schedules, flexibility, and consistent precision, even under demanding timelines.

Quality is more than dimensional accuracy. It is our commitment. Certified according to ISO 9001, we use tactile, optical, and scanning measurement technologies to verify every component. From first article inspection to full inspection series, we deliver measurable and documented reliability.

We ensure that your components arrive safely and sustainably. Our packaging solutions are tailored to each part, ranging from reusable systems to custom inserts. This reduces waste and provides optimal protection during transport.

Beyond manufacturing, we offer assembly, functional testing, surface finishing, and heat treatment. This comprehensive service ensures that your components are fully tested, refined, and ready for direct integration, all delivered from a single source.